Synergy by design

full-service supplier offering dip-coating, ultrasonic cleaning, and bespoke Turn-Key Solutions to industries.

A comprehensive approach to providing customers with truly effective standard and bespoke solutions.

Developed through years of industry experience, we combine our expertise of chemistry, engineering and manufacturing to deliver a full-service provision to industries not replicated anywhere else.

We not only provide efficient machine processes along with distribution of top consumable products, but also work with clients in order to develop and optimise the right process for each application.

This harmonised approach, alongside our experienced team, gives us the depth to make better machines and an overall unrivalled service to customers, now and for the future.

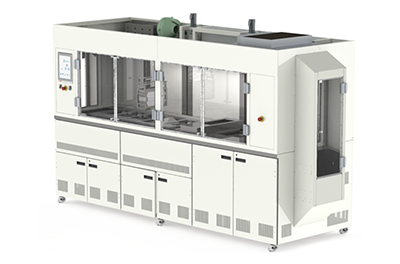

Unitech Shyre’s W200 automated wet bench ultrasonic cleaning system was developed specifically for the semiconductor industry. The W200 is a...

Unitech Shyre is a leader in automatic FPI machines. FPI (Fluorescent Penetrant Inspection) is a non-destructive inspection method that is...

Automated solutions with precision results, the PC200 provides a range of production options and adaptive for a number of configurations...

Our Benchtop Ultrasonic Baths provide high performance tool cleaning and lens stripping applications. Designed for consistent results with digital accuracy.

Unitech Shyre’s W200 automated wet bench ultrasonic cleaning system was developed specifically for the semiconductor industry. The W200 is a...

Unitech Shyre is a leader in automatic FPI machines. FPI (Fluorescent Penetrant Inspection) is a non-destructive inspection method that is...

Automated solutions with precision results, the PC200 provides a range of production options and adaptive for a number of configurations...

Our Benchtop Ultrasonic Baths provide high performance tool cleaning and lens stripping applications. Designed for consistent results with digital accuracy.

Industries We Serve

Precision Optics

Precision Optics OPHTHALMIC

OPHTHALMIC SEMICONDUCTOR

SEMICONDUCTOR MEDICAL/ORTHOPAEDIC

MEDICAL/ORTHOPAEDIC AUTOMOTIVE

AUTOMOTIVE METAL FINISHING

METAL FINISHING Precision Optics

Precision Optics

Unitech Shyre is an industry leader in developing and delivering specialised cleaning processes and equipment to the precision optical industry. With extensive experience in this field bringing value to every application.

OPHTHALMIC

OPHTHALMIC

Since inception, we have sought to redefine the forefront of dip coating technologies within the ophthalmic industry, developing and manufacturing cutting-edge dip coating and cleaning equipment, to deliver our comprehensive range of leading coating processes.

SEMICONDUCTOR

SEMICONDUCTOR

Unitech Shyre Precision Cleaning Machines are the leading choice for semiconductor industry professionals looking for reliable and efficient cleaning solutions. Our systems are designed to meet the highest standards of cleanliness and precision, with a range of options and customisations available to suit the most demanding processes.

MEDICAL/ORTHOPAEDIC

MEDICAL/ORTHOPAEDIC

The team have extensive experience providing cleaning, passivating and FPI systems to the medical and orthopaedic sectors for over 30 years. Several industry firsts were introduced by founding members of the company.

AUTOMOTIVE

AUTOMOTIVE

Applications in the automotive industry cover a wide range of components and processes. From metal finishing and degreasing to precision cleaning, component passivation and coating.

METAL FINISHING

METAL FINISHING

Solvent based cleaning systems optimised for the Electronics Industry are designed to provide superior cleaning performance for Printed Circuit Boards (PCBs) and other electronic components. Our machines are used for removing flux residues, applying conformal coatings, as well as performing a wide range of other cleaning tasks.

Level of Service

Unitech Shyre can provide a true turnkey solution encompassing state of the art cleaning & coating machinery, specially formulated chemicals & coatings, and proven processes. The result is a solution that can be easily and seamlessly implemented for any customer.

In taking responsibility for the entire process we can ensure that our customers receive a seamless and integrated solution that meets their individual needs and requirements. Unitech Shyre provides a single point of contact to the customer, reducing complications and delivering reliable and robust solutions.

Unitech Shyre offer a wide range of standard machines capable of meeting most process needs. If a customer has a unique requirement we are able to offer a truly bespoke solution. Utilising our in house design and engineering teams we can work with the customer to achieve the best possible solution.

We are committed to developing deep and lasting relationships with our customers, helping us to better understand their needs and requirements. From the initial design and engineering phase to the installation and commissioning of equipment, and through ongoing maintenance and support; we are with our customers every step of the way.