The Clean Air Trolley by Shyre allows storage of components in an ULPA filtered cabinet, which can then be used to transport clean components from one area of production to another without risk of introducing airborne contamination.

UV air sterilisation is also available as an additional option on request.

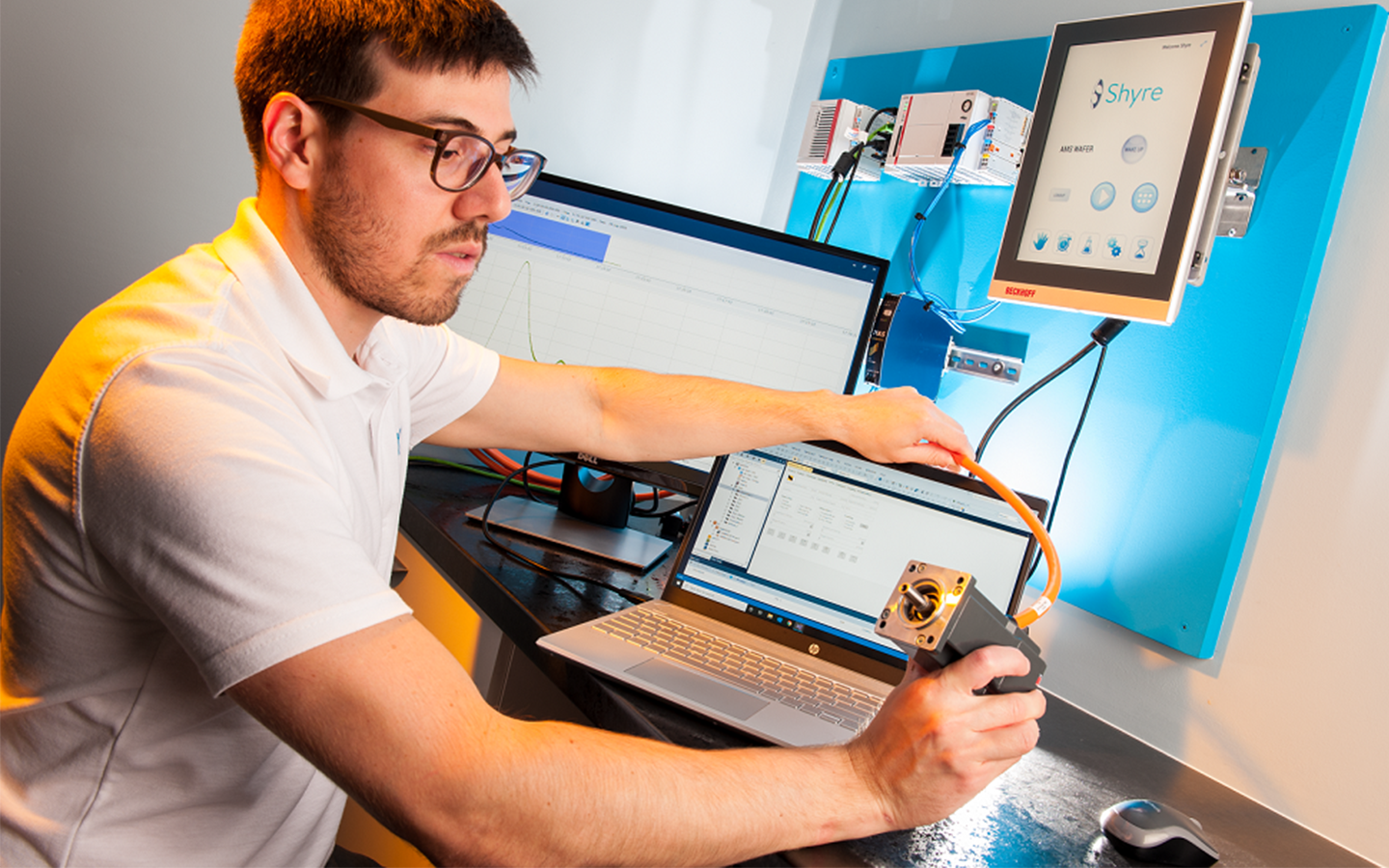

Shyre also provides bespoke software development, both standalone, integrated into existing systems or to compliment custom developed projects. This allows software to be tailored to suit the specific application, ensuring that the software meets the exact customer requirements.

Additionally, Shyre provides process and chemistry development, which is vital for process optimisation. This ensures that the customer’s process is operating at its maximum efficiency and is producing the desired results.

Shyre was founded on a vision of developing new chemistry and processes with photochromic technologies. Over the years we have utilised the expertise to develop many new technologies and process solutions for customer’s unique application needs. Now, the company regularly provides the services of process and chemistry development, both as part of larger turn-key automation projects and as standalone process development or optimisation of customer’s existing processes.

Oftentimes our customers will come to us with their component and request that a cleaning and/or coating process is developed for the specific application.

To deliver the best for our customers, we can provide a range of solutions including:

Shyre have access to a vast array of chemistry and coating technologies, and will often have your solution to hand.

Should a process or application require specific development or adaptation of chemistry in order to realise or improve the process, then custom materials can be developed.

Shyre specialise in design and manufacture, in particular, of photochromic and tinting technologies.

Unitech Shyre’s ability to produce customised bespoke solutions to meet customers specific applications is enabled by its comprehensive range of services. This includes 3D CAD modelling of fully automated machines, bespoke software development, custom tooling design, along with process and chemistry development.

Our 3D CAD modelling (Solidworks) capability provides a virtual representation of new equipment prior to manufacture; allowing customers to evaluate and review designs and layouts prior to production.

Our 3D CAD modelling (Solidworks) capability provides a virtual representation of new equipment prior to manufacture; allowing customers to evaluate and review designs and layouts prior to production.

Custom part tooling/jigging design is an important part of many projects; this enables the customer to create a unique tool that is tailored to their specific application.

Custom design and production of bespoke tooling and part jigging

We also provides bespoke software development, both standalone, integrated into existing systems or to compliment custom developed projects. This allows software to be tailored to suit the specific application, ensuring that the software meets the exact customer requirements.

Additionally, providing process and chemistry development, which is vital for process optimisation. This ensures that the customer’s process is operating at its maximum efficiency and is producing the desired results.

Our company was founded on a vision of developing new chemistry and processes with cutting edge optical technologies. Over the years we have utilised the expertise to develop many new technologies and process solutions for customer’s unique application needs. Now, the company regularly provides the services of process and chemistry development, both as part of larger turn-key automation projects and as standalone process development or optimisation of customer’s existing processes.

Our company was founded on a vision of developing new chemistry and processes with cutting edge optical technologies. Over the years we have utilised the expertise to develop many new technologies and process solutions for customer’s unique application needs. Now, the company regularly provides the services of process and chemistry development, both as part of larger turn-key automation projects and as standalone process development or optimisation of customer’s existing processes.

Process Development and Validation

Oftentimes our customers will come to us with their component and request that a cleaning and/or coating process is developed for the specific application.

To deliver the best for our customers, we can provide a range of solutions including:

Chemical and Coating Development

We have access to a vast array of chemistry and coating technologies, and will often have your solution to hand.

Should a process or application require specific development or adaptation of chemistry in order to realise or improve the process, then custom materials can be developed.